Project description: We are a project partner in the ARTEM project (Aircraft noise Reduction Technologies and related Environmental iMpact) that aims at the maturing of promising novel concepts and methods which are directly coupled to new low noise and disruptive 2035 and 2050 aircraft configurations.

The project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 769350.

Last week, members of PVS research have just returned from a week long wind tunnel testing in INCAS, Bucharest. The team was performing tests on a composite design model wing with modular attachment points for different Distributed Electrical Propulsion (DEP) configurations, designed and built by PVS within the ARTEM European project.

Figure 1: The members of PVS in the INCAS wind tunnel.

ARTEM (Aircraft noise Reduction Technologies and related Environmental iMpact) is a four-year European Union‘s Horizon 2020 research project devoted to the development of novel noise reduction technologies for low-noise 2035 and 2050 aircraft configurations.

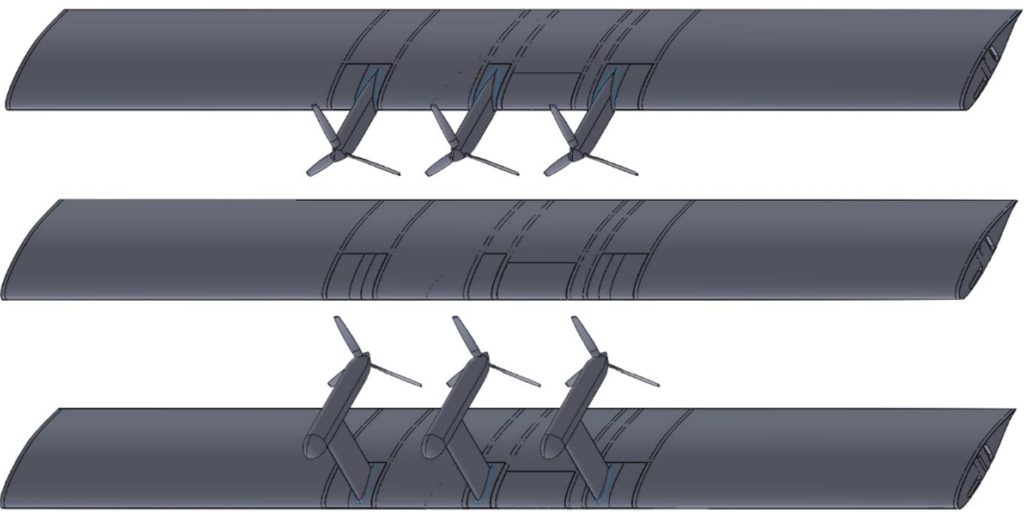

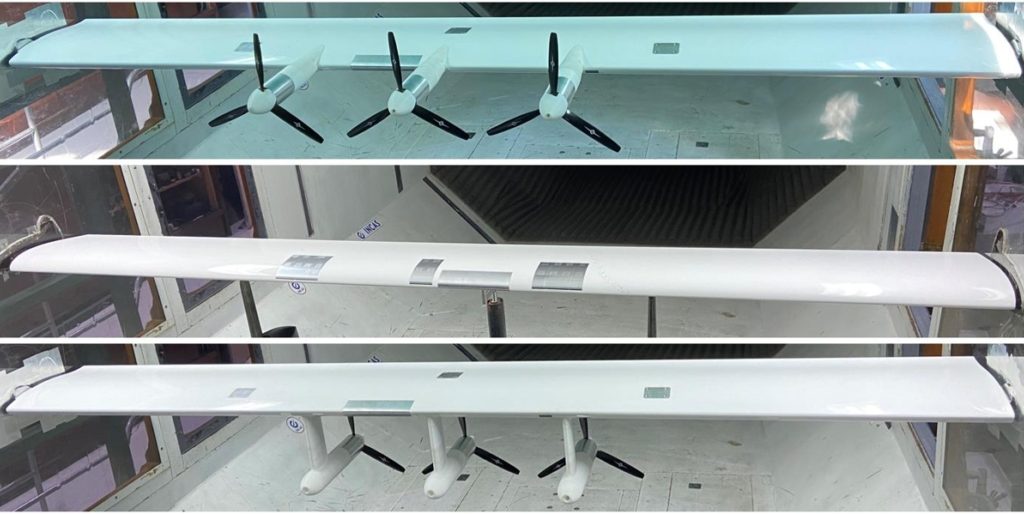

PVS involvement in ARTEM project is on the investigation of novel DEP aircraft configurations, whose global objective is the investigation and mitigation of noise emissions of DEP systems. Together with three ARTEM partners, VKI, ONERA and INCAS, PVS explored two different configurations of such integration. The mock-up is composed out of the main wing and three propellers positioned in front of the wing, resulting in the “tractor configuration”, or on top of the wing, resulting in the “pusher configuration”.

Figure 2: 3D model of a tractor configuration (top), a clean wing configuration (mid) and a pusher configuration (below).

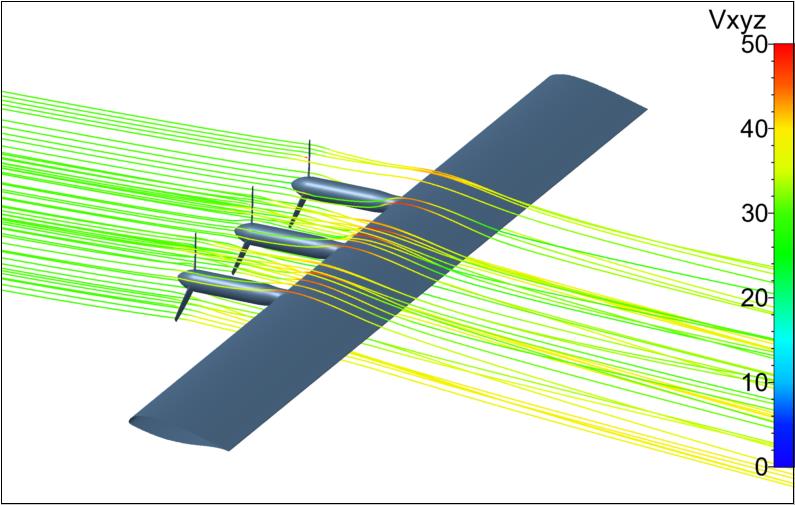

Firstly, PVS worked on the general definition of the DEP mock-up, defining all necessary functional requirements for the experiment. The conceptual and preliminary design phases followed with the selected concept having a modular design allowing for spanwise, chordwise and vertical positioning of the propellers in both configurations. An aerofoil profile, especially suited for DEP systems, was carefully designed. During the preliminary and detailed design phases a thorough numerical assessment of the DEP wing and subsystems was done using RANS/URANS CFD.

Figure 3: An example of a CFD simulation for a tractor configuration. Velocity vectors passing the three propellers are depicted.

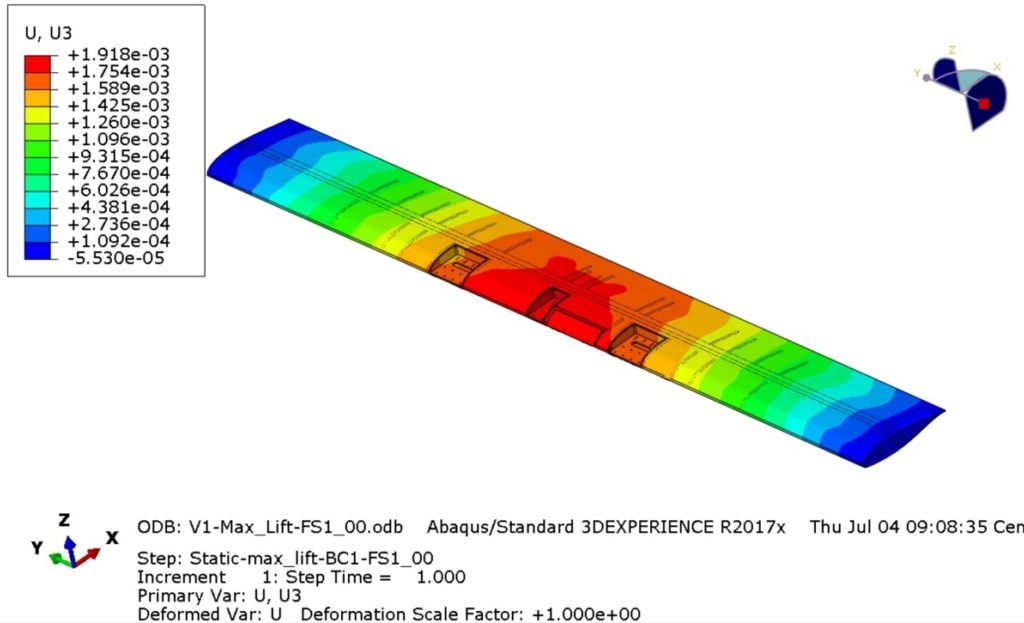

In the detailed design phase, PVS finished the geometry and dimensioned the structure to withstand the loads imposed in the wind tunnel with minimal deflections. The wing shell and main spar were dimensioned to have less than 2 mm deflection on a 2500 mm span in the nominal 30m/s loading condition at maximum AoA. The structure was also tested numerically with FEM, which predicts a factor of safety of 30 in the nominal design case.

Figure 4: FEM analysis showing vertical displacement in mm in the nominal case.

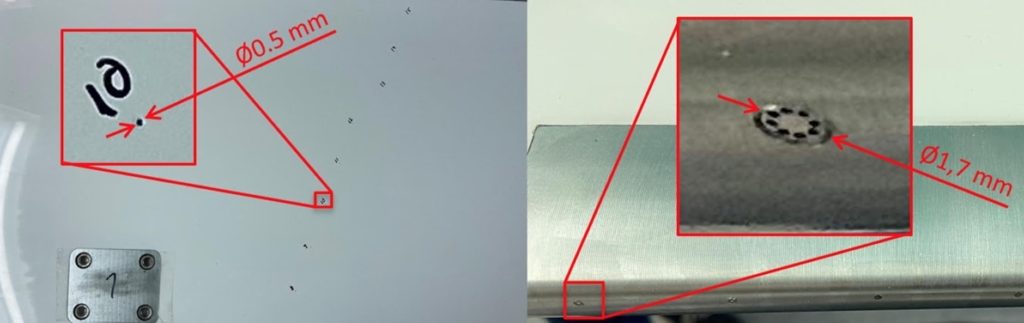

Once the design was frozen, PVS finished the complete technical documentation for the moulds, integral wing parts and modules. The model wing was produced to the highest production standards using modern manufacturing technologies. Innovative production solutions were developed when facing very limited space within a 300 mm chord and merely 50 mm maximum thickness of the cross section. As an example, 32 0,5 mm diameter pressure orifices surround the wing upper and lower shell from the leading to the trailing edge. The mock-up seamlessly combines composite, aluminium and 3D printed parts in order to ensure quality and technical excellence while retaining a competitive price.

Figure 5: Static pressure orifices in wing shell (left), modular dynamic pressure sensors incorporation on leading edge (right).

Finally, PVS operated the mock-up during the wind tunnel tests at INCAS to speeds up to 50 m/s. Both configurations were successfully tested at INCAS wind tunnel in order to identify the noise sources and their relative weights between the wing and propeller regions, and between the tonal and broadband contributions. Experimental data will be at great help to the task partners to analyze parametric sensibilities of the noise in order to identify parameters of interest for acoustic reuction.

Figure 6: Assembled tractor configuration (top), a clean wing configuration (mid) and a pusher configuration (below).

DEP type of propulsion became feasible with the introduction of state-of-the-art electric motors and offers numerous potential noise reduction configurations. It offers more degrees of freedom during the integration of a propulsion system on an aircraft. This is why PVS is heavily invested in facilitating research of such topics through implementing our broad spectre of knowledge and experience to bring ideas to life in a very fast cycle.

Most favourable configuration with respect to the acoustic and aerodynamic performance will be selected by PVS at the end of the project, and full recommendations for designing the state-of-the-art DEP system will be provided.